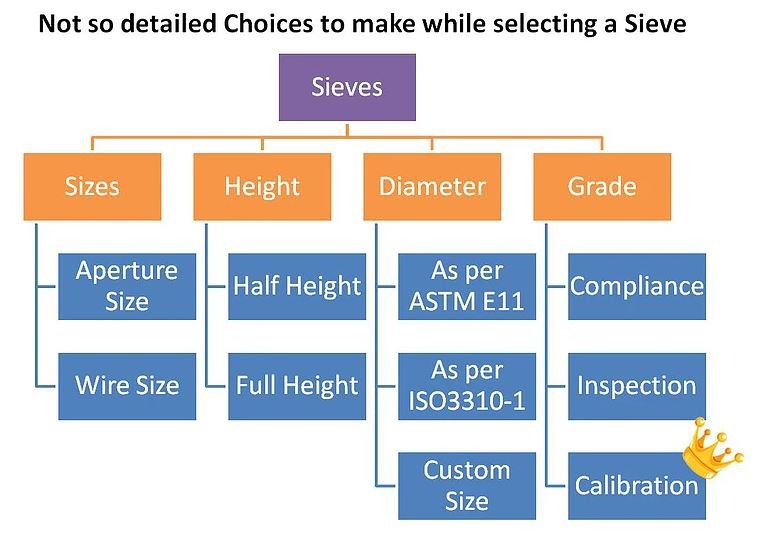

A Lab technician faces a challenge while choosing the Right Sieve for his Sieving application from the vast amount of choices he has. I shall try to give you a rough chart of sieve selection. The most important of them is the Sieve Grades..

The Grades and the Standards…

The ISO standard for analytical wire mesh sieve (ISO3310-1) was revised quite a while ago. The ASTM E11 followed the suite and also introduced three types of certifications for Sieves. This divides the Sieves in grades. As we can see from the chart

- Compliance grade Sieve

- Inspection grade Sieve

- Calibration grade sieve

Dont’ worry, its not quite complicated as it sounds!

They are All the Same or Are they? all that matters is the Confidence Level…

ESSENTIALLY ALL THESE SIEVES ARE MADE WITH THE SAME FABRIC OF WIRE-MESH WITH THE SAME MANUFACTURING PROCESS. But, a Calibration grade Sieve will cost you a bomb as against a compliance grade sieve.

Here’s essentially why…

- Issuing a Compliance certificate is mandatory for a manufacturer who claims conformance to ASTM E11 or ISO3310-1 standard. Well, the certificate doesn’t or may not give any statistical data that is generated during inspection of the Sieve. The Certificate just states that, the Sieve Complies with blah..blah..blah standard.

- Upon request, the manufacturer should provide an Inspection grade certificate. Inspection grade Sieve certificate mentions the statistical data. Statistical Data includes average aperture size, separately in both the warp and weft direction of the wire cloth. Well, the manufacturer may charge you extra for this data.

- For both Compliance and Inspection grade sieve certification, the same number of apertures are checked. This is essentially the reason why their prices shouldn’t be poles apart. Thou shall have predicted value of confidence level of standard deviation at 99% for the process of certification of compliance and inspection grade sieves.

- Many manufacturers underrate compliance grade sieve. This is because the users many a times don’t read standards of compliance. As per standard both compliance and Inspection grade Sieves should be equally accurate and precise.

- On the other hand sits the Calibration grade sieve. Calibration grade Sieve which gets checked for more than double the number of holes than their less fortunate counterparts. ( Inspection grade Sieve and Compliance grade Sieve). Thou shall have predicted value of confidence level of standard deviation at 99.73% for the process of calibration grade certification. Important: the manufacturer must give you results that shall be stated for the number of apertures and wire diameters measured . For a 53 Micron Sieve, that, number is a whopping >500 measurements of the tiny holes!

What does that mean for you?

- Well, if you are doing super critical work.. (Rocket Science, Nuclear Science, Critical Medicine) day in and day out heavily relying on Sieving results the 0.73% increase in confidence level is a substantial difference. It is recommended to use calibration grade Sieve set.

- On the other hand if your testing is not a matter of life and death. (e.g: Grading Minerals or Cosmetics or Foods for that matter) but the testing is frequent, then you should have one Calibration grade sieve. Keep the calibration grade Sieve set in wraps. Use the Calibration grade Sieve set only to check if your compliance or inspection grade sieve set is giving right results.

- if you’re testing is not a matter of life and death. (e.g: Grading Minerals or Cosmetics or Foods for that matter) and the testing is infrequent, then you should use compliance or inspection grade Sieve set.

- Compliance grade sieve set can only be bought. After using it for a while, when you send it back to manufacturer. It shall come back as Inspection grade after its verification is done. We do owe you the little stats in that case.