VCAT: The Versatile Testing and Control Equipment for your Green Sand Plant

VCAT is one of the most comprehensive systems available in the market and comes in 5 Modular variants which, means each system can be customised to your requirements.

VCAT-1 & VCAT-2: The On-line testing equipment

Are Testing systems which can be installed above the moulding machine, they take sample from the sand falling in the moulding machine and test it. These machines have a typical testing time between 5 to 12 seconds depending on which parameters user wishes to check.

VCAT-3 & VCAT-4: The Online Testing & Control equipment

These are testing and control systems which are comprised of multiple other systems i.e:

- A VCAT-1 or VCAT-2 placed near Mixer either by drilling a hole in mixer shell to take sample out for testing or at the discharge gate of the mixer to take sample during sand discharge. Typically when user wishes to do compactability/ moisture in two steps (Major water Dose- Testing (1)- TRim Water Dose- Testing(2)- Discharge), the equipment is attached to the mixer shell to take the sample and typically when user wishes to do control next batch based on results of previous batch and moisture % in current batch which is in batch hopper at the time of starting mixing cycle, then the equipment (VCAT- 1 or 2 ) is fitted at the discharge gate of the mixer.

- VDOSE: A High precision Water dosing system: The VDOSE is capable of dosing at 4.2 lps with an accuracy of +/-100 ml. It also raises alarms when water pump performance deteriorates or flow rates dwindle.

- VHOP: Hopper Moisture Measurement system: This system checks moisture in the Batch hopper of the mixer and is a must when user has chosen to correct next batch on the basis of results obtained during the previous batch. Typically when user wishes to do compactability/ moisture in two steps (Major water Dose- Testing (1)- TRim Water Dose- Testing(2)- Discharge), this equipment can be optionally bought.

- Batch hopper temperature monitoring and set-point correction system: This system monitors temperature of the sand coming in Mixer’s batch hopper as well as ambient temperature. This enables user to upload to the SCADA system a table of temperature vs compactability loss. This in-turns ensure that, irrespective of temperatures, compactability at point of use remains stable.

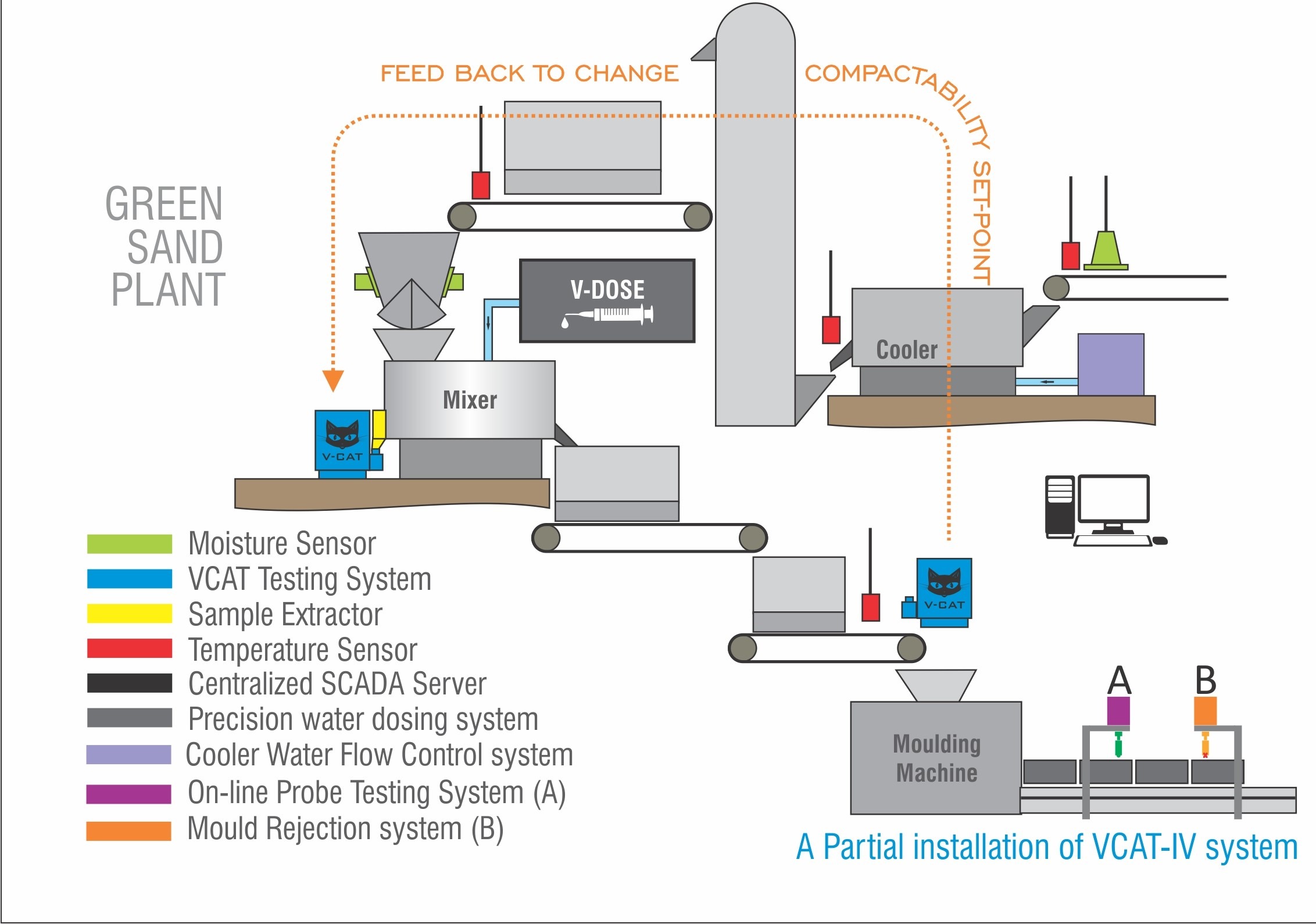

A Closed loop system:

When a VCAT-1 or 2 is installed above the moulding machine (at point of use) , it can give feed-back to VCAT system fitted at mixer to effectively control compactability at point of use. Refer Diagram below to understand exactly what it means.

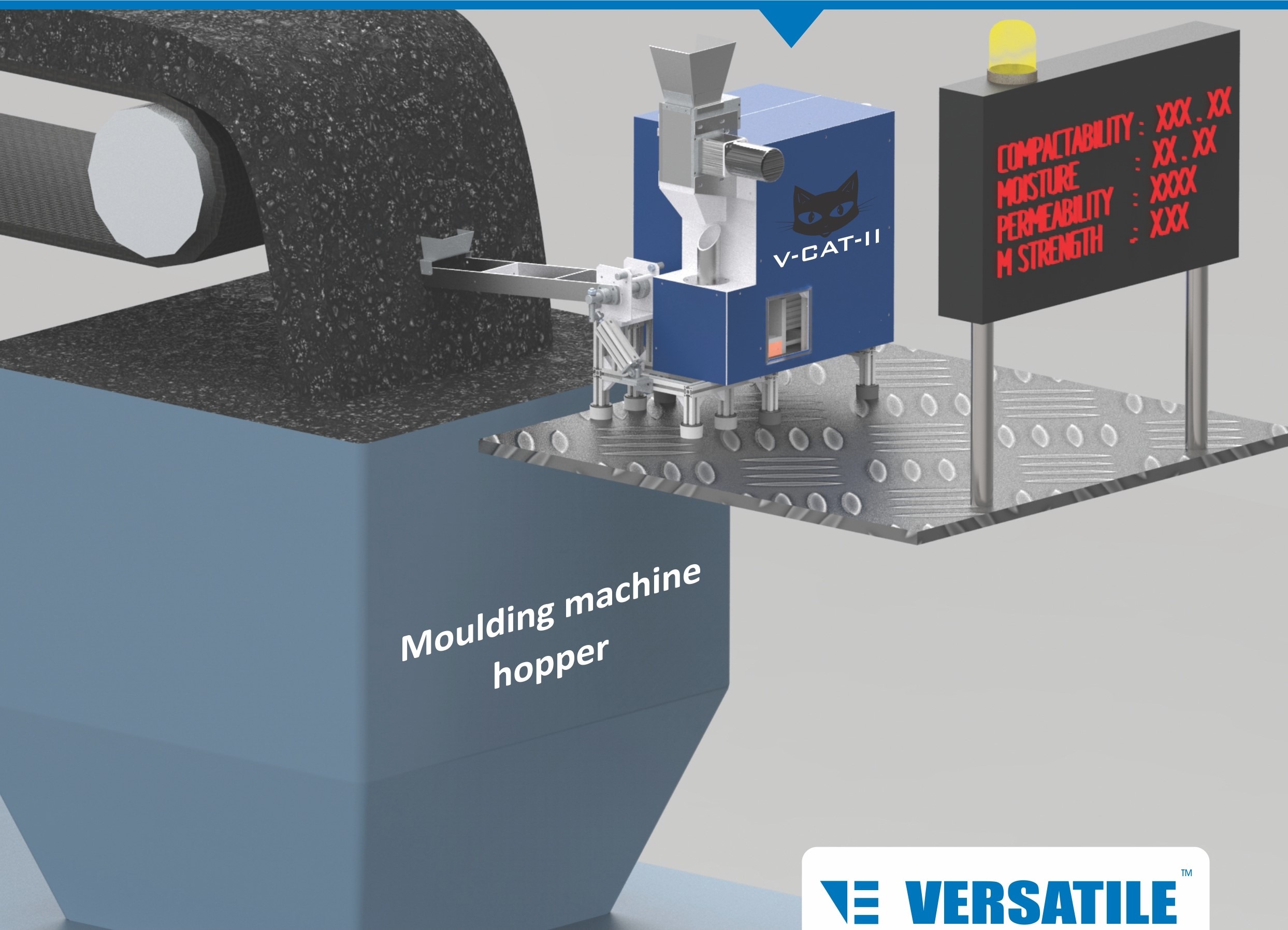

Following is a typical installation of online green sand testing system near moulding machine:

VCAT testing on moulding machine

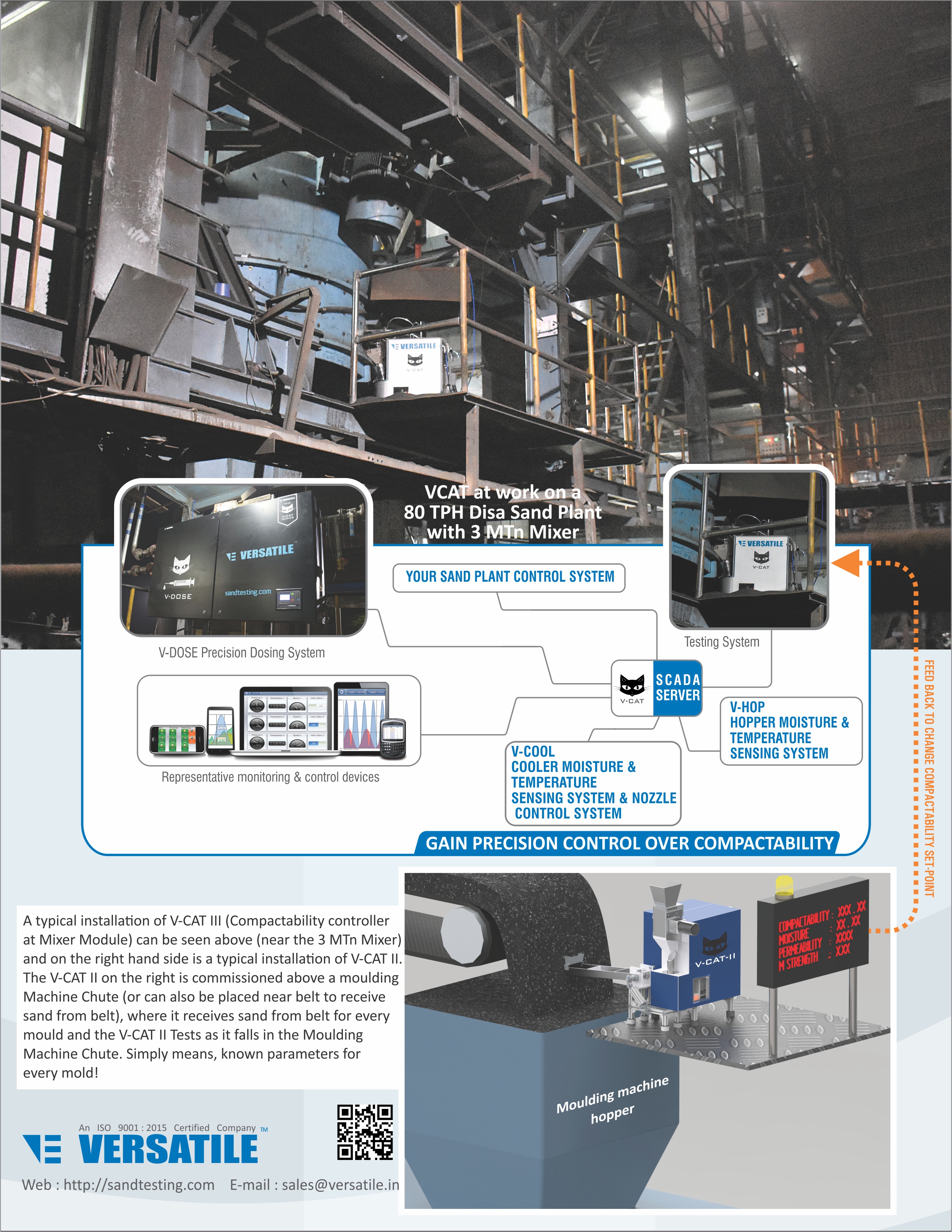

Also check below, A VCAT-3 system placed near Mixer.

VCAT testing and control system for green sand